At the current level of development, process automation is one of the approaches to process management based on the use of information technology. This approach allows you to manage operations, data, information and resources through the use of computers and software that reduce the degree of human participation in the process, or completely exclude it.

Processes Automation

The main goal of automation is to improve the quality of process execution. An automated process has more stable characteristics than a process performed in manual mode. Process automation can improve productivity, reduce process execution time, reduce cost, and increase the accuracy and stability of operations performed in many cases.

Process automation has covered many industries and fields of activity: from production processes to shopping in stores. Almost every company has automated processes regardless of the size and scope of the organization. The process approach provides for uniform automation principles for all processes.

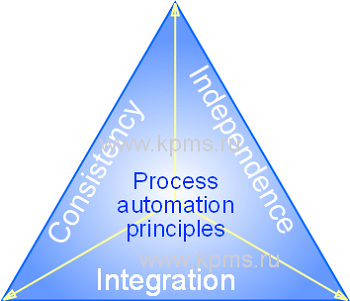

Processes automation principles

The principles of automation for all levels and all types of processes will remain the same despite the fact that process automation can be performed at different levels. The general principles set the conditions for the effective execution of processes in automatic mode and establish rules for automatic process management.

The main principles of process automation are:

- the consistency principle. All actions in the automated process must be coordinated with each other and with the inputs and outputs of the process. A violation of the process execution may occur in case of a mismatch of actions.

- the integration principle. The automated process should be able to integrate into the overall environment of the organization. Integration is performed differently at different levels of automation, but the essence of the principle remains unchanged. Process automation should ensure the interaction of the automated process with the external environment (in relation to this process).

- the independence principle. The automated process should be performed independently, without human involvement, or with minimal human control. A person should not interfere in the process if the process is carried out in accordance with the established requirements.

The general principles are detailed depending on the considered level of automation and specific processes. For example, the production processes automation includes such principles as the principle of specialization, the principle of proportionality, the principle of continuity, etc.

Processes automation levels

Processes automation is necessary to support management at all levels of the company hierarchy. The levels of automation are determined depending on the control level at which the processes automation is performed.

Management levels are usually divided into operational, tactical and strategic.

Automation levels are distinguished in accordance with these levels:

- lower level of automation or the level of performers. Automation of regularly running processes is carried out at this level. Automation of processes is aimed at performing operational tasks (for example, execution of the production process), maintaining set parameters (for example, autopilot operation), maintaining certain operating modes (for example, the temperature regime in a gas boiler).

- production management level or tactical level. Automation of processes at this level ensures the distribution of tasks between various lower-level processes. Examples of such processes are production management processes (production planning, service planning), resource management processes, documents, etc.

- enterprise management level or strategic level. Automation of processes at the enterprise management level provides solutions to analytical and predictive tasks. This level of automation is necessary to support the top management work of the organization. It is aimed at financial, economic and strategic management.

Automation of processes at each of these levels is provided through the use of various automation systems (CRM systems, ERP systems, OLAP systems, etc.). All automation systems can be divided into three basic types.

Types of automation systems include:

- invariable systems. These are systems in which the sequence of actions is determined by the configuration of equipment or process conditions and cannot be changed during the process.

- programmable systems. These are systems in which the sequence of actions can change depending on the specified program and process configuration. The selection of the necessary sequence of actions is carried out due to a set of instructions that can be read and interpreted by the system.

- flexible (self-adjusting) systems. These are systems that are able to select the necessary actions in the process of work. Changing the configuration of the process (the sequence and conditions of operations) is carried out based on information about the progress of the process.

These types of systems can be used at all levels of process automation individually or as part of a combined system.

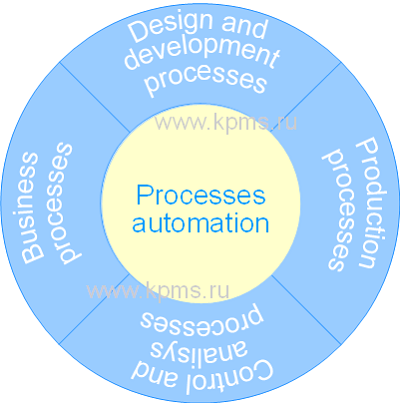

Automated processes types

There are enterprises and organizations that produce products or provide services in every sector of the economy. All these enterprises can be divided into three groups, depending on their "remoteness" in the chain of processing of natural resources.

The first group of enterprises is enterprises that extract or produce natural resources. Such enterprises include, for example, agricultural producers, oil and gas producing enterprises.

The second group of enterprises is enterprises that process natural raw materials. They manufacture products from raw materials extracted or produced by enterprises of the first group. Such enterprises include, for example, enterprises of the automotive industry, steel enterprises, enterprises of the electronic industry, power stations, etc.

The third group is the service sector enterprises. Such organizations include, for example, banks, educational institutions, healthcare facilities, restaurants, etc.

Common groups of processes related to the production of products or the provision of services can be distinguished for all enterprises.

Such processes include:

- business processes. These are processes that ensure interaction within the organization and with external stakeholders (consumers, suppliers, supervisory authorities, etc.). This category of processes includes marketing and sales processes, interaction with consumers, financial, personnel, material planning and accounting processes, etc.

- design and development processes. These are processes related to the development of a product or service. Such processes include the processes of development planning, collection and preparation of initial data, project execution, control and analysis of design results, etc.

- production processes. These are the processes that necessary for the production of products or the provision of services. All production and technological processes belong to this group. They also include demand planning and capacity planning processes, logistics processes, and service processes.

- control and analysis processes. This group of processes is associated with the collection and processing of information about the execution of processes. Such processes include quality control processes, operational management, inventory control processes, etc.

Most of the processes belonging to these groups can be automated. There are classes of systems that provide automation of these processes.

An example of "Technical specifications" for the automation of some enterprise subsystems can be viewed and purchased in the "Quality Management" online store.

The TS for the "Warehouses" subsystem is an example of a technical specification for automating the management of an enterprise warehouses.

This document is an example of a real Technical specification, on the basis of which a warehouse automation system of an industrial enterprise was selected and implemented.

The document includes 26 pages. The document format is Microsoft Word 2002. It is compatible with all versions of MS Word. The document allows editing and making changes.

The TS "Document flow" subsystem is an example of a technical specification for automating the management of the document management process.

This document is an example of a real Technical specification, on the basis of which a document management automation system of an industrial enterprise was selected and implemented.

The document includes 17 pages. The document format is Microsoft Word 2002. It is compatible with all versions of MS Word. The document allows editing and making changes.

The TS for the "Purchases" subsystem is an example of a technical specification for automating procurement processes and supplier management.

This document is an example of a real Technical specification, on the basis of which a procurement automation and supplier management system of an industrial enterprise was selected and implemented.

The document includes 23 pages. The document format is Microsoft Word 2002. It is compatible with all versions of MS Word. The document allows editing and making changes.

Processes automation strategy

Process automation is a complex and laborious task. It is necessary to follow to a certain automation strategy in order to successfully solve this problem. It allows you to improve processes and get a number of significant advantages from automation.

The strategy can be formulated as follows:

- understanding the process. It is necessary to understand the existing process with all its details in order to automate the process. The process must be fully analyzed. The inputs and outputs of the process, the sequence of actions, the relationship with other processes, the composition of the process resources, etc. must be defined.

- simplification of the process. It is necessary to simplify the process after analyzing the process. Unnecessary operations that do not have value should be reduced. Individual operations can be combined or performed in parallel. Other technologies of process execution may be proposed to improve the process.

- process automation. Automation of processes can be performed after the process has been simplified as much as possible. It is the easier to automate the process if the actions of it simpler and the automated process will work more efficient.

Processes automation advantages

Automation of processes can significantly improve the quality of management and product. Automation gives a significant effect and enables the organization to significantly improve its work when implementing the QMS. It is necessary to evaluate the advantages of performing processes in automatic mode before making a decision about automating processes.

Process automation provides the following advantages:

- it is increased the speed of performing repetitive tasks. The same tasks can be performed faster due to the automatic mode, because automated systems are more accurate in their actions and are not subject to a decrease in efficiency from the time of operation.

- the quality of work is improving. The exclusion of the human factor significantly reduces variations in the execution of the process, which leads to a reduction in the number of errors and, accordingly, increases the stability and quality of the process.

- control precision increases. It becomes possible to save and take into account more data about the process due to the use of information technologies in automated systems than with manual control.

- parallel execution of tasks. Automated systems allow you to perform several actions simultaneously without loss of quality and accuracy of work. This speeds up the process and improves the quality of the results.

- quick decision-making in typical situations. Decisions related to typical situations are made much faster in automated systems than with manual control. This improves the characteristics of the process and avoids inconsistencies at subsequent stages.

Process automation is not always advisable despite the obvious advantages. It may turn out that process automation is not required or economically unprofitable after analysis and optimization.

Manual execution of processes may be preferable to automation in some situations:

- the process operations are difficult to automate. Some operations of the process can be very difficult to automate from a technological or economic point of view.

- short product life cycle. The automation of the process may not be feasible if a product has to be developed and implemented in a short period of time, or the duration of its existence on the market is short. Manual execution of processes will be less costly and faster than automation.

- unique or single products. A consumer needs a product with unique characteristics of manual labor. Such product can be released only if the processes are performed manually.

- sharp fluctuations in demand. A change in demand for a product requires a change in production volumes. Such changes are easier to make when the process is performed manually.